Predictive Maintenance & Condition Monitoring

- Real-time asset health tracking via IoT integrations.

- AI-driven failure prediction and root cause analysis.

- Threshold-based alerts and automated intervention requests.

CARL’s APM suite is built on a modular, web-native architecture that supports:

The central CMMS/EAM engine, 100% HTML-based, no plug-ins required.

GIS and BIM-enabled spatial asset visualization.

Real-time data ingestion and action triggering from connected devices.

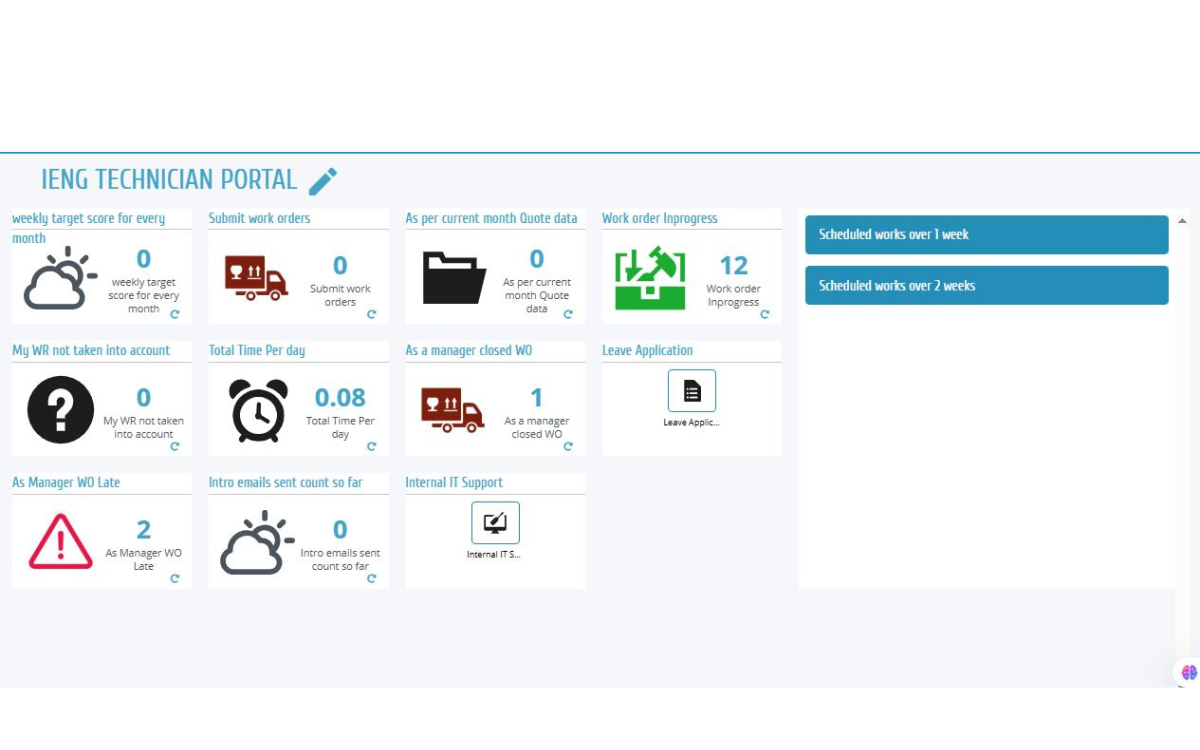

Tailored for industrial maintenance and TPM traceability.

All modules are interoperable via REST APIs, Web Services, and configurable interfaces—ensuring seamless integration with your existing IT ecosystem.

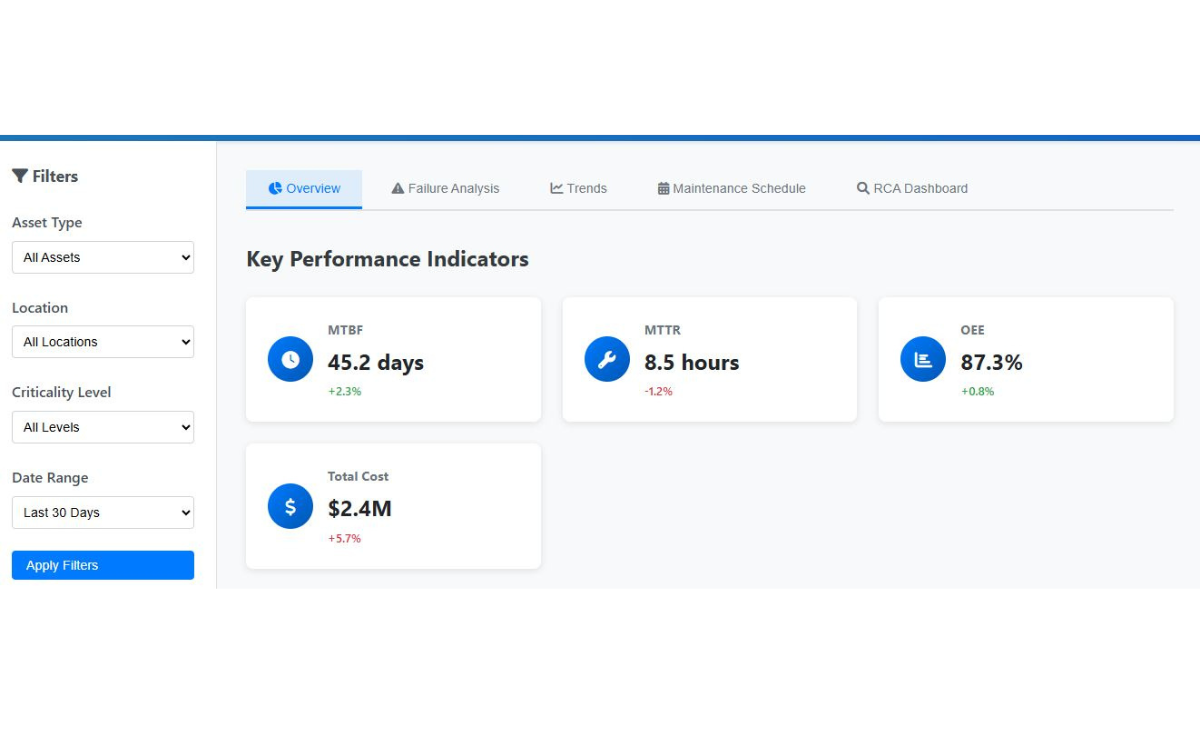

Define and track maintenance performance indicators directly from CARL Source. Organize KPIs by sites, asset classes, teams, or contracts for consistent governance.

Build role-based dashboards (operational, planner, executive). Slice by period, asset, location, or cost center; drill from KPIs to work orders, parts, and failure codes.

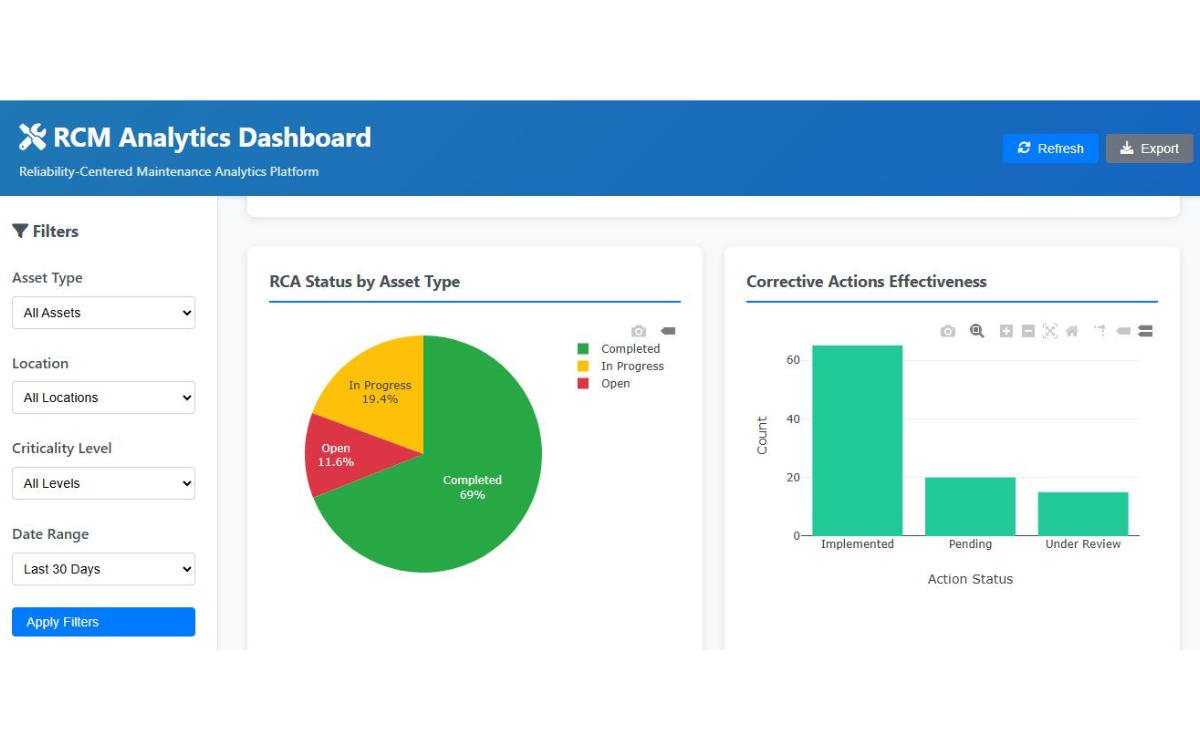

Publish interactive reports and Reliability-Centered Maintenance (RCM) scorecards in Power BI. Analyze failure modes, risk ranking, downtime, denial reasons, cost, and spares consumption.

Explore RCM portal: rcm.ieng.tech

CARL isn’t just software it’s your strategic partner in operational excellence. Let us help you unlock the full potential of your assets with a suite that’s complete, compliant, and built for your sector.